Interested in a signal building group?

Re: Interested in a signal building group?

Dave,

The attached photo is of the internals from a door lock servo from a 90s Rover. I thought this might well work signals, but on 12 volts the action is very fast. I was surprised when I opened it up because I was convinced it was a solenoid.The whole box of tricks is about 4" x 2" x 1" so it will take up a lot of space.

If you think the RC servo action is too quick you could connect the crank to the pull wire with a tension spring which will create a delaying action as the pull is applied. That should also smooth the jitters and the variable speed you mentioned earlier.

As we discussed previously I will assemble the ladders, hoops and handrails. If I do it, the silver solder is at my expense for this group. I have also discussed bending the U bolts if you supply the material cut to length and screwed.

The signal post you have dimensioned is presumably for a single stop signal. The original scheme as drawn by Johny has stop and distant signals on the same post. Would these require taller posts? As I advised earlier I have materials here for two posts and could make them up taller than yours if need be. Also on these there is I think some sort of linkage that prevents the distant clearing if the stop signal is on. Are we intending to try replicate that?

In respect of the bases is it possible to make them demountable to reduce the space required for storage?

Eddie

The attached photo is of the internals from a door lock servo from a 90s Rover. I thought this might well work signals, but on 12 volts the action is very fast. I was surprised when I opened it up because I was convinced it was a solenoid.The whole box of tricks is about 4" x 2" x 1" so it will take up a lot of space.

If you think the RC servo action is too quick you could connect the crank to the pull wire with a tension spring which will create a delaying action as the pull is applied. That should also smooth the jitters and the variable speed you mentioned earlier.

As we discussed previously I will assemble the ladders, hoops and handrails. If I do it, the silver solder is at my expense for this group. I have also discussed bending the U bolts if you supply the material cut to length and screwed.

The signal post you have dimensioned is presumably for a single stop signal. The original scheme as drawn by Johny has stop and distant signals on the same post. Would these require taller posts? As I advised earlier I have materials here for two posts and could make them up taller than yours if need be. Also on these there is I think some sort of linkage that prevents the distant clearing if the stop signal is on. Are we intending to try replicate that?

In respect of the bases is it possible to make them demountable to reduce the space required for storage?

Eddie

-

Dave Noble

- Fat Controller

- Posts: 164

- Joined: Mon Feb 27, 2006 12:38 am

Re: Interested in a signal building group?

Hope you can make it Guy.

Thanks for the info on the door mechanism Eddy, looks like it won't be suitable unfortunately. And for the offer of work, I'll update the previous post.

The dimensions I have given will be suitable for one or two arms, so stick to the sizes given. There is indeed slotting to prevent the distant clearing while the stop signal is on. However, I've mentioned this to Jonny and he says he'll incorporate in the electronics. I suppose it could be included in the mechanism, if everything works as it should there would be no conflict, but it may be safer to leave it out for now.

Bases. If you want to make yours detachable that's fine, I'm only making suggestions. At the moment I think they'll be about 170 x 180mm which isn't much larger than the footprint of the signal. My intention is to slot them into a box, where they will be securely held and protected.

Thanks for the info on the door mechanism Eddy, looks like it won't be suitable unfortunately. And for the offer of work, I'll update the previous post.

The dimensions I have given will be suitable for one or two arms, so stick to the sizes given. There is indeed slotting to prevent the distant clearing while the stop signal is on. However, I've mentioned this to Jonny and he says he'll incorporate in the electronics. I suppose it could be included in the mechanism, if everything works as it should there would be no conflict, but it may be safer to leave it out for now.

Bases. If you want to make yours detachable that's fine, I'm only making suggestions. At the moment I think they'll be about 170 x 180mm which isn't much larger than the footprint of the signal. My intention is to slot them into a box, where they will be securely held and protected.

-

Jonny Ward

- Engine Driver

- Posts: 24

- Joined: Fri Feb 03, 2006 5:17 pm

- Location: Mordor, or Coalville as its spelt around here.

Re: Interested in a signal building group?

I finally had a play at controlling a servo from an Arduino last night. Although it wasn't quite functioning in the manor I had hoped (The problem being the programming, or more accurately, the programmer....), there was no jitter. So long as the RC signal wire is kept reasonably short I don't think it will be a problem.Dave Noble wrote: Servos. I'm still struggling with this. If we connect the operating wire directly to the servo arm (very easy) we can only use a small amount of movement, and that will be jittery, that's how servos are, and any jitteriness is magnified at the signal arm. Using the full movement of say 180 degrees is most easily done with a short throw horn connected to the wire, but the movement is now like a toggle, ie slow to start, fast at the mid point, then slows down gradually at the end. Signal arms don't move like that. Another alternative could be to use the servo shaft as a winch, and wind up or pay out some fine chain. I think this perhaps may be smoother and it would give a constant speed, not right, but better. If we think a winch is a good idea, a miniature geared motor would give a smoother feed, but they are more expensive, £20 ish. Thoughts?

-

Dave Noble

- Fat Controller

- Posts: 164

- Joined: Mon Feb 27, 2006 12:38 am

Re: Interested in a signal building group?

That's good news Jonny, I'll have another go with mine.

Some shackles arrived. They look very good to me, as Eddy says, they have a screwed pin rather than a plain one with a split pin. The "handle" on the end of the pin is a bit lumpy and not machined centrally in the pin, but could be filed off. I'm guessing we'd rather use these pins and assemble with Loctite or such, than drill the threads out and make new pins? Though if we made new pins we could nip the shackles up a little so they were a closer fit on the arms. Thoughts?

I bought the turnbuckles just to see what they're like. This is the M1.4 size, and does have left and right hand threads. The wires are 0.5 and 0.8mm. The smaller is closer to scale, and I can't see it being any more difficult to use than the larger size. I assume that it's all from the same place, China, so I'll get some ordered if no-one objects. I've found 100 metres for only £17.

I had a phone call from Chris who suggested the use of Muscle wire for operating the signals. This stuff contracts when heated, usually by passing a current through it. It's used quite a lot on table top railways for point operation etc. Though it's not a bad idea, I think it could be difficult in our size. Has anyone used it? There's a lot of info at http://cdn.sparkfun.com/datasheets/Comp ... CF1140.pdf

Some shackles arrived. They look very good to me, as Eddy says, they have a screwed pin rather than a plain one with a split pin. The "handle" on the end of the pin is a bit lumpy and not machined centrally in the pin, but could be filed off. I'm guessing we'd rather use these pins and assemble with Loctite or such, than drill the threads out and make new pins? Though if we made new pins we could nip the shackles up a little so they were a closer fit on the arms. Thoughts?

I bought the turnbuckles just to see what they're like. This is the M1.4 size, and does have left and right hand threads. The wires are 0.5 and 0.8mm. The smaller is closer to scale, and I can't see it being any more difficult to use than the larger size. I assume that it's all from the same place, China, so I'll get some ordered if no-one objects. I've found 100 metres for only £17.

I had a phone call from Chris who suggested the use of Muscle wire for operating the signals. This stuff contracts when heated, usually by passing a current through it. It's used quite a lot on table top railways for point operation etc. Though it's not a bad idea, I think it could be difficult in our size. Has anyone used it? There's a lot of info at http://cdn.sparkfun.com/datasheets/Comp ... CF1140.pdf

Re: Interested in a signal building group?

Hi Dave-all

I like what you have no point in doing it again re shackles ect we could replace the pin with a S/S screw would look nicer.

For recoil I seem to thick memory wire 1 get hot 2 only moves a bit we are I suggest going to need a bit more movement.

I will try and follow up on the lead I sent you last night (may be open in morning if not then Monday) Jonny any thoughts.

Looks simple but your the man and it means cables Rc would be nice. Anyway see you all on Sunday.

Ben

I like what you have no point in doing it again re shackles ect we could replace the pin with a S/S screw would look nicer.

For recoil I seem to thick memory wire 1 get hot 2 only moves a bit we are I suggest going to need a bit more movement.

I will try and follow up on the lead I sent you last night (may be open in morning if not then Monday) Jonny any thoughts.

Looks simple but your the man and it means cables Rc would be nice. Anyway see you all on Sunday.

Ben

-

Jonny Ward

- Engine Driver

- Posts: 24

- Joined: Fri Feb 03, 2006 5:17 pm

- Location: Mordor, or Coalville as its spelt around here.

Re: Interested in a signal building group?

Yes, two of the Signals at Gilling were fitted with Muscle wire. There worked fine, so long as the wind didn't blow. When it was windy, the breeze had such a cooling effect that the signals either took an age to come off or didn't come off at all, though this shouldn't be a problem for us. The only issue I can foresee is that with all this kit being powered by battery, what kind of current will they draw when the signal is off, and is that any more or less than servo (I'm thinking that servo will draw more current, but only whilst the servo is in motion).Dave Noble wrote: I had a phone call from Chris who suggested the use of Muscle wire for operating the signals. This stuff contracts when heated, usually by passing a current through it. It's used quite a lot on table top railways for point operation etc. Though it's not a bad idea, I think it could be difficult in our size. Has anyone used it?

-

Dave Noble

- Fat Controller

- Posts: 164

- Joined: Mon Feb 27, 2006 12:38 am

Re: Interested in a signal building group?

Jonny,

I reckon from the tables in the link, that we'd need to have at least 300mA at each signal when off. Adding on for the other bits and losses through the cables probably makes it unsuitable. Unless someone knows otherwise.

I reckon from the tables in the link, that we'd need to have at least 300mA at each signal when off. Adding on for the other bits and losses through the cables probably makes it unsuitable. Unless someone knows otherwise.

-

Guy Harding

- Cleaner

- Posts: 14

- Joined: Tue Jan 06, 2009 2:56 pm

- Location: Southam Warwickshire

Re: Interested in a signal building group?

Re: Interested in a signal building group?

Notes from the signalling group meeting 28/6/20155

Base construction.:-

Top plate 1.5 mm steelike

18mmPVC spacer CNC routed to profile

1 or 1.5mm steel or PVC bottom plate

Note: All drivers at Shildon will have the signalling system explained to them before they are allowed to drive.

Signalling Types

Type 1 Single post Single arm Home (Main starter) 5 qty

Type 2 RH bracket signal Main arm plus shunt arm 2 qty

Type 3 Single post Single arm plus shunt arm below 1 qty

Type 4 LH bracket two main arms plus shunt arm on bracket 1 qty

Type 5 Single post Home plus distant 1 qty

Type 6 Single post Single arm distant 3 qty

Build Allocation

Type 1 AW Eddy JW DN GC

Type 2 BL building both

Type 3 DN

Type 4 GH

Type 5 JW

Type 6 AW Eddy GC

Components to make

Posts Steel tube Alan to machine

Arms Laser cut DN to make press tool AW to press

Ladders Eddy to solder them up from steel

Lights Awaiting drawings DN to chase up

Spectacle plates Press from steel BL to investigate tooling options

programming JW

Bases as above

Electronics JW

Cranks Laser cut

BracketsDN to draw up and cast

Wire bracket

saddle

stop rod bracket

crank bracket

ladder saddle

balance lever bracket

signal arm bracket

lamp bracket

Base construction.:-

Top plate 1.5 mm steelike

18mmPVC spacer CNC routed to profile

1 or 1.5mm steel or PVC bottom plate

Note: All drivers at Shildon will have the signalling system explained to them before they are allowed to drive.

Signalling Types

Type 1 Single post Single arm Home (Main starter) 5 qty

Type 2 RH bracket signal Main arm plus shunt arm 2 qty

Type 3 Single post Single arm plus shunt arm below 1 qty

Type 4 LH bracket two main arms plus shunt arm on bracket 1 qty

Type 5 Single post Home plus distant 1 qty

Type 6 Single post Single arm distant 3 qty

Build Allocation

Type 1 AW Eddy JW DN GC

Type 2 BL building both

Type 3 DN

Type 4 GH

Type 5 JW

Type 6 AW Eddy GC

Components to make

Posts Steel tube Alan to machine

Arms Laser cut DN to make press tool AW to press

Ladders Eddy to solder them up from steel

Lights Awaiting drawings DN to chase up

Spectacle plates Press from steel BL to investigate tooling options

programming JW

Bases as above

Electronics JW

Cranks Laser cut

BracketsDN to draw up and cast

Wire bracket

saddle

stop rod bracket

crank bracket

ladder saddle

balance lever bracket

signal arm bracket

lamp bracket

Re: Interested in a signal building group?

Guy, All,

Looks like you had a good meeting and covered a lot of ground.

I have two signal posts under construction to the dimensions in Dave's earlier posting i.e. 700mm high. Could I have confirmation that Type 1 and 6 posts conform to that size? I have enough material to make two more bottom tubes at 366mm long and will machine them this week and deliver to Alan at Ryedale next Sunday. (Whoops! I read AW and got Alan Warden instead of Alan Woods (apologies Alan), so I'll do them and make arrangements to get them where ever they are needed)

No mention in the components list of the U bolts. Dave and I have discussed collaboration in their production (see earlier posts).

Is Dave still intending to have the ladder stiles, hoops and handrails laser cut and holed?

Is the signalling diagram going to be issued to us so we can see how we get to 13 signals? I take it we are deferring ground signals for the time being.

Eddie

Looks like you had a good meeting and covered a lot of ground.

I have two signal posts under construction to the dimensions in Dave's earlier posting i.e. 700mm high. Could I have confirmation that Type 1 and 6 posts conform to that size? I have enough material to make two more bottom tubes at 366mm long and will machine them this week and deliver to Alan at Ryedale next Sunday. (Whoops! I read AW and got Alan Warden instead of Alan Woods (apologies Alan), so I'll do them and make arrangements to get them where ever they are needed)

No mention in the components list of the U bolts. Dave and I have discussed collaboration in their production (see earlier posts).

Is Dave still intending to have the ladder stiles, hoops and handrails laser cut and holed?

Is the signalling diagram going to be issued to us so we can see how we get to 13 signals? I take it we are deferring ground signals for the time being.

Eddie

-

Dave Noble

- Fat Controller

- Posts: 164

- Joined: Mon Feb 27, 2006 12:38 am

Re: Interested in a signal building group?

Fistly, thanks to those who attended the meeting yesterday, I think it was well worth while. There was Ben, Jonny, Guy, Alan, Graham and Liz. Thanks also to Annie for making the sandwiches, they tasted fine, though Annie and Liz decided to off for a proper meal instead of sharing ours!

The general feeling was that the posts will be fine as described, and Alan offered to machine them, but because he was travelling home by train, couldn't carry the material back with him. Do you want the material sending, or shall I just get on with them?

I had assembled one base, and the basic idea was accepted, but because acrylic can be a bit delicate, and the three layers showed significant joints (because the laser seems to make a slightly V shaped cut), Ben suggested a middle section of PVC. The top could be steel, and the bottom again steel, but let in slightly so that it doesn't get scratched (and rust) on a concrete floor. This will add useful weight to the base. Ben offered to acquire and machine the PVC. I glued some acrylic parts together onto the post bottom to represent the steel servo mountings, and this was OK.

Ben brought some 3D sample saddles. I thought they should be to a higher resolution, this should be possible. I'll do some more drawings and then Ben will grow some and we'll get them cast in brass so that we can check overall shrinkage before getting the final batch of castings. Whitemetal was rejected on the grounds of limited strength.

Jonny brought his big drawing, and this was discussed at length. I still don't understand signalling. From that we drew up a list of what signals are required, and then they were allotted to builders in a fairly random manner. Hopefully, Jonny will post a copy of this final version. He's been tinkering with his Arduino and shows promise of being able to come up with a working control system. At the moment, there'll be a 4 core cable connecting all the signals in each area to the box, though no decision was made on how the lever frame will be built. There may be a need to motorise 3 or 4 turnouts, and some may need detection. Signals will not be detected, and interlocking will be entirely electrical. We will incorporate a method of operating the signals "manually" from a 12v supply, so that we can play with them at home.

I'll update the previous post which I think I'll just call "The List" for now. If in doubt, refer to that.

Eddy. It is assumed that all single posts will be 700mm long, though to be honest, there's no reason not to make some a bit longer or shorter for a bit of variation if anyone wants to. So long as they can be seen (if not obeyed) by drivers. U bolts and ladders etc, no change, still as on The List. Signal diagram, as mentioned above. Ground signals, probably none to be used for now.

The general feeling was that the posts will be fine as described, and Alan offered to machine them, but because he was travelling home by train, couldn't carry the material back with him. Do you want the material sending, or shall I just get on with them?

I had assembled one base, and the basic idea was accepted, but because acrylic can be a bit delicate, and the three layers showed significant joints (because the laser seems to make a slightly V shaped cut), Ben suggested a middle section of PVC. The top could be steel, and the bottom again steel, but let in slightly so that it doesn't get scratched (and rust) on a concrete floor. This will add useful weight to the base. Ben offered to acquire and machine the PVC. I glued some acrylic parts together onto the post bottom to represent the steel servo mountings, and this was OK.

Ben brought some 3D sample saddles. I thought they should be to a higher resolution, this should be possible. I'll do some more drawings and then Ben will grow some and we'll get them cast in brass so that we can check overall shrinkage before getting the final batch of castings. Whitemetal was rejected on the grounds of limited strength.

Jonny brought his big drawing, and this was discussed at length. I still don't understand signalling. From that we drew up a list of what signals are required, and then they were allotted to builders in a fairly random manner. Hopefully, Jonny will post a copy of this final version. He's been tinkering with his Arduino and shows promise of being able to come up with a working control system. At the moment, there'll be a 4 core cable connecting all the signals in each area to the box, though no decision was made on how the lever frame will be built. There may be a need to motorise 3 or 4 turnouts, and some may need detection. Signals will not be detected, and interlocking will be entirely electrical. We will incorporate a method of operating the signals "manually" from a 12v supply, so that we can play with them at home.

I'll update the previous post which I think I'll just call "The List" for now. If in doubt, refer to that.

Eddy. It is assumed that all single posts will be 700mm long, though to be honest, there's no reason not to make some a bit longer or shorter for a bit of variation if anyone wants to. So long as they can be seen (if not obeyed) by drivers. U bolts and ladders etc, no change, still as on The List. Signal diagram, as mentioned above. Ground signals, probably none to be used for now.

-

Richard Phillips

- Fat Controller

- Posts: 178

- Joined: Mon Feb 23, 2009 6:14 pm

Re: Interested in a signal building group?

Since all signals seem to be covered by the existing members of the group, can I then elect to make "spares"? And to be honest since I'm "down South" an don't get up to Shildon they probably will be. I'd be interested in doing two, maybe something a bit more fancy than a single post so a "Type 2" and a "Type 6" since we need a few of those and they're as simple as they get also.

I can probably silver solder my own parts like ladders and turn posts to length if we're doing kits of parts.

I saw a micro version of the Leonardo (but I'll need to speak to Jonny again about this) so perhaps this is something that can be let into the base of a signal, so each signal has some "intelligence", I did chat to Jonny about the behaviours and I wondered whether we could flash these boards with several patterns, we'd just need a method of selecting the "programme" they will run. I would guess a distant would be fairly straightforward and we work upwards from that.

I can probably silver solder my own parts like ladders and turn posts to length if we're doing kits of parts.

I saw a micro version of the Leonardo (but I'll need to speak to Jonny again about this) so perhaps this is something that can be let into the base of a signal, so each signal has some "intelligence", I did chat to Jonny about the behaviours and I wondered whether we could flash these boards with several patterns, we'd just need a method of selecting the "programme" they will run. I would guess a distant would be fairly straightforward and we work upwards from that.

Re: Interested in a signal building group?

Hi Dave,

Just a thought on the bases I think we need to make the post as part/ attached to the top steel plate, your example with the post passing up though the base will only work without all the bits added to the posts Suggest thread inside post and have a bolt up from below Ie inside PVC base.

This would allow builds posts with parts with aybe one of you electric wizards do your stuff, inside the PVc sub bases, We then combine the bases to the posts and add in the operation wire servo to lower crank.

Just a thought on the bases I think we need to make the post as part/ attached to the top steel plate, your example with the post passing up though the base will only work without all the bits added to the posts Suggest thread inside post and have a bolt up from below Ie inside PVC base.

This would allow builds posts with parts with aybe one of you electric wizards do your stuff, inside the PVc sub bases, We then combine the bases to the posts and add in the operation wire servo to lower crank.

-

Dave Noble

- Fat Controller

- Posts: 164

- Joined: Mon Feb 27, 2006 12:38 am

Re: Interested in a signal building group?

Ben, I also had thoughts, but for different reasons. Certainly my original method will only work with a bare post, but I didn't see that as a problem. If the PVC section is machined right through, which I think is what we were thinking of, then it won't be possible to fix the servos to it, we need a top on for that, which I think is what you are saying. But, whether the post is bolted or silver soldered to the top, we still have to solder the brackets for the servos to the underside of the top. I'm wondering, how thick does the top have to be so that we can silver solder to it without it buckling?

My preference would be to silver solder the servo brackets and post to a steel top, add the PVC layer, securely fix the ladder, and call that the structural basis of the signal. But, there is no reason why you shouldn't fix the top to the PVC, add the electrics, then bolt the post and fix the ladder on later. What would you do, tap the post M14 or 9/16, and use a hollow bolt (for the wires to the lamp)? It still leaves the problem of silver soldering the servo brackets though. Or could we get away with soft solder? What do you/others think?

The top should have been fastened with c/s bolts, but I was in a hurry. The two round holes are for the operating rods, the other two for the ladder.

The little subplate from acrylic would have been in steel, but it was convenient to do it this way for a trial. You can see the space for electronics, the round hole was for a slug of lead, if we think they need more stability, maybe not. The small slot is for the ladder feet, I imagine filling the hole with Araldite to fix them.

Richard, thanks for offering to make spares, and, the current plan is to fit an Arduino to each signal, there seems to be plenty space for that.

My preference would be to silver solder the servo brackets and post to a steel top, add the PVC layer, securely fix the ladder, and call that the structural basis of the signal. But, there is no reason why you shouldn't fix the top to the PVC, add the electrics, then bolt the post and fix the ladder on later. What would you do, tap the post M14 or 9/16, and use a hollow bolt (for the wires to the lamp)? It still leaves the problem of silver soldering the servo brackets though. Or could we get away with soft solder? What do you/others think?

The top should have been fastened with c/s bolts, but I was in a hurry. The two round holes are for the operating rods, the other two for the ladder.

The little subplate from acrylic would have been in steel, but it was convenient to do it this way for a trial. You can see the space for electronics, the round hole was for a slug of lead, if we think they need more stability, maybe not. The small slot is for the ladder feet, I imagine filling the hole with Araldite to fix them.

Richard, thanks for offering to make spares, and, the current plan is to fit an Arduino to each signal, there seems to be plenty space for that.

Re: Interested in a signal building group?

Hi Richard

Happy for you to do one of the required bracket signals I can do the middle yard/dave yard junction then you will might take on the exit from Daves yard , Jonny will i hope advise on post layout I believe it two arm starter with both arm level.

Dave my thought is to do top plate steel with post either bolted or silver soldered ( hollow bolt) PVC wth machined pockets with servo on plate are you thinking steel for this? much as you show the two signal and base could be built seperatly only requiring a link from servo arm to post lower crank.

Happy for you to do one of the required bracket signals I can do the middle yard/dave yard junction then you will might take on the exit from Daves yard , Jonny will i hope advise on post layout I believe it two arm starter with both arm level.

Dave my thought is to do top plate steel with post either bolted or silver soldered ( hollow bolt) PVC wth machined pockets with servo on plate are you thinking steel for this? much as you show the two signal and base could be built seperatly only requiring a link from servo arm to post lower crank.

-

Dave Noble

- Fat Controller

- Posts: 164

- Joined: Mon Feb 27, 2006 12:38 am

Re: Interested in a signal building group?

I think it's getting too complicated and messy.

Is the reason for using PVC that it is tougher than acrylic? If so, why not make a PVC version of the acrylic base in the pictures. Using 20mm grey PVC, could Ben rout out the cavities to say 17mm deep, cut the holes for the post and 4 bolts, profile the outside, and drill holes for the bolts which hold the bottom on in one go on his mill? We then pass them on to someone else to mill the little slots for the ladder. We also get a small laser cut steel plate like the acrylic one in the pictures. This plate has the servo brackets silver soldered to it, it's small so unlikely to buckle. Then either,

For those who want, silver solder the post to the steel plate and assemble as in the pictures, or,

For those who want, have smaller post holes and only fix the steel plate, the post is bolted on later.

This relies on 3mm of PVC carrying the load of the post, is it strong enough? We've done away with the questionable top steel plate, but end up with a much neater job, no joins on the side, only 4 screws in the rustproof top, which may not even need painting. It is lighter, but we can easily glue in a lead slug, I've loads of lead we can cast, and another bay window roof to go at if we run out.

The bottom plate can be 1mm acrylic (Chris could laser cut) let into a 2mm recess so the middle is clear of the floor. This gives an internal depth of 15mm, or 13mm for the servos, just enough.

Is the reason for using PVC that it is tougher than acrylic? If so, why not make a PVC version of the acrylic base in the pictures. Using 20mm grey PVC, could Ben rout out the cavities to say 17mm deep, cut the holes for the post and 4 bolts, profile the outside, and drill holes for the bolts which hold the bottom on in one go on his mill? We then pass them on to someone else to mill the little slots for the ladder. We also get a small laser cut steel plate like the acrylic one in the pictures. This plate has the servo brackets silver soldered to it, it's small so unlikely to buckle. Then either,

For those who want, silver solder the post to the steel plate and assemble as in the pictures, or,

For those who want, have smaller post holes and only fix the steel plate, the post is bolted on later.

This relies on 3mm of PVC carrying the load of the post, is it strong enough? We've done away with the questionable top steel plate, but end up with a much neater job, no joins on the side, only 4 screws in the rustproof top, which may not even need painting. It is lighter, but we can easily glue in a lead slug, I've loads of lead we can cast, and another bay window roof to go at if we run out.

The bottom plate can be 1mm acrylic (Chris could laser cut) let into a 2mm recess so the middle is clear of the floor. This gives an internal depth of 15mm, or 13mm for the servos, just enough.

Last edited by Dave Noble on Wed Jul 01, 2015 6:24 pm, edited 1 time in total.

Re: Interested in a signal building group?

Sorry to put a spanner in the works but I can't laser cut PVC it gives of poisonous and corosive fumes and can damage the machine.

-

Dave Noble

- Fat Controller

- Posts: 164

- Joined: Mon Feb 27, 2006 12:38 am

Re: Interested in a signal building group?

OK Chris, I've updated the post.

Re: Interested in a signal building group?

HI dave /all

20mm PVC I cut and mill one Saturday norning would do all 13/14 or so Rough cost for plate 250/ 250/ 20 is £12 whill see what I can do on this cost today. Dave have you some Dims for the bases.

Ben

20mm PVC I cut and mill one Saturday norning would do all 13/14 or so Rough cost for plate 250/ 250/ 20 is £12 whill see what I can do on this cost today. Dave have you some Dims for the bases.

Ben

-

Jonny Ward

- Engine Driver

- Posts: 24

- Joined: Fri Feb 03, 2006 5:17 pm

- Location: Mordor, or Coalville as its spelt around here.

Re: Interested in a signal building group?

Apologies for not getting these up on the forum earlier. My excuse is a week sat in a class room being bombarded with rules and regulations!

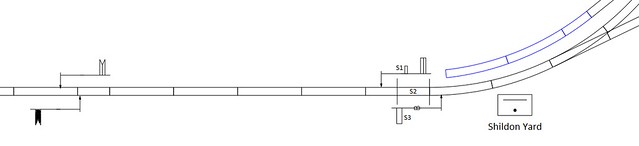

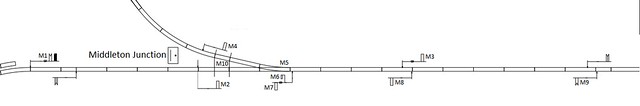

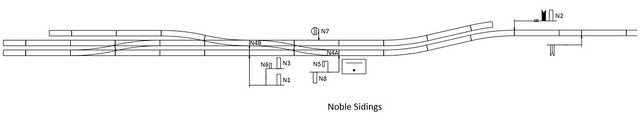

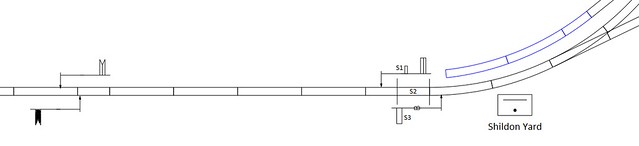

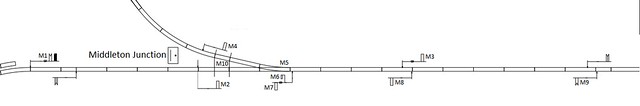

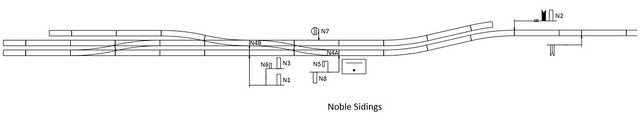

Following the meeting at Dave's, here are the latest plans for Shildon Yard, Middleton Junction and Noble Sidings. I've made a minor alteration to Noble Sidings, it doesn't alter the signalling, but reduces the number of motorised points down to three. Is everyone happy with this?

I've already created locking tables, and circuitry for the crossing lights and control. I'll be looking at making the block bell's shortly, and when the micro computers arrive, having a go at the code for communication.

Following the meeting at Dave's, here are the latest plans for Shildon Yard, Middleton Junction and Noble Sidings. I've made a minor alteration to Noble Sidings, it doesn't alter the signalling, but reduces the number of motorised points down to three. Is everyone happy with this?

I've already created locking tables, and circuitry for the crossing lights and control. I'll be looking at making the block bell's shortly, and when the micro computers arrive, having a go at the code for communication.

-

Richard Phillips

- Fat Controller

- Posts: 178

- Joined: Mon Feb 23, 2009 6:14 pm

Re: Interested in a signal building group?

I had started thinking about how signal control is to be done with the Arduinos, and it did occur to me we might be re-inventing the wheel - this is of course before I started looking into other possible solutions.

The one that came to mind was Digital Command Control (DCC) - this already provides a method for controlling accessories - but after investigating, it is a bit limited as far as I can see. It does offer the advantage of passing digital commands over two wires (in model railways - the rails) unfortunately this won't work for us as most of us have conductive wheelsets, and also would probably be defeated by any wiring for block sections.

DCC is quite simple in that it provides an addressable command, therefore Signal 15 could be sent an instruction, but I've not read a great deal about feedback, if we want to prove the signal/lamps electrically.

What Jonny proposes takes into account ramps and locking, something DCC makes no provision for as far as I can see (without additional hardware/software). There was a good youtube video of someone using an Arduino with DCC (there are libraries available for programming) driving servos also interacting with switches, which in some ways seems attractive as you can then put your very oversized GL5 signals to work on your O/OO gauge railway after you've finished with the at Shildon , but I think I've discounted this idea, but it might be a neat thing to do, have a signal that could be controlled either by responding to a series of external inputs, or responding to a digital DCC command - maybe it's possible to combine the two, with a central processor reading all the point ramp and signal aspects and just sending instructions to the signals, but I think Jonny knows what he's doing

, but I think I've discounted this idea, but it might be a neat thing to do, have a signal that could be controlled either by responding to a series of external inputs, or responding to a digital DCC command - maybe it's possible to combine the two, with a central processor reading all the point ramp and signal aspects and just sending instructions to the signals, but I think Jonny knows what he's doing  although I wonder if there might be a way of turning locking tables into instructions without having to programme each signal for it's station individually, or a multi-function program that can be selected at runtime by an external input.

although I wonder if there might be a way of turning locking tables into instructions without having to programme each signal for it's station individually, or a multi-function program that can be selected at runtime by an external input.

The one that came to mind was Digital Command Control (DCC) - this already provides a method for controlling accessories - but after investigating, it is a bit limited as far as I can see. It does offer the advantage of passing digital commands over two wires (in model railways - the rails) unfortunately this won't work for us as most of us have conductive wheelsets, and also would probably be defeated by any wiring for block sections.

DCC is quite simple in that it provides an addressable command, therefore Signal 15 could be sent an instruction, but I've not read a great deal about feedback, if we want to prove the signal/lamps electrically.

What Jonny proposes takes into account ramps and locking, something DCC makes no provision for as far as I can see (without additional hardware/software). There was a good youtube video of someone using an Arduino with DCC (there are libraries available for programming) driving servos also interacting with switches, which in some ways seems attractive as you can then put your very oversized GL5 signals to work on your O/OO gauge railway after you've finished with the at Shildon